Fluid Management

Why automate?

With the Brisco Systems eMix 1500, concentration and level variations are things of the past.

Manual effort and associated maintenance costs are significantly reduced.

Our new calculator will show you what you can save!

Just enter your details and find out the level of savings. If you have any questions, you can always contact our qualified staff.

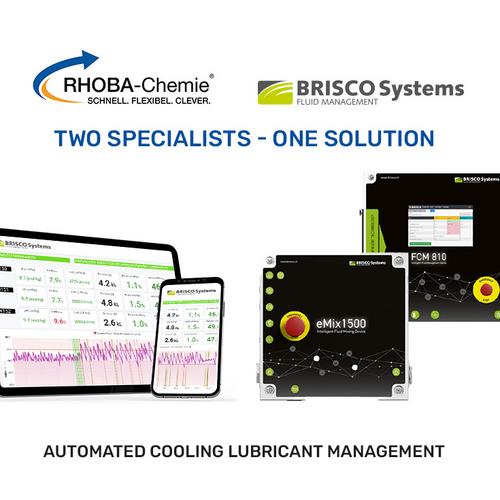

Visualization of all measurement data

Modern KSS management saves time and money. Benefit from longer tool life and up to 25% concentrate savings, as well as reduction of working hours.

Real-time data on all tanks

KSS data is saved, visualized and processed further

Can be easily integrated into existing CRM systems

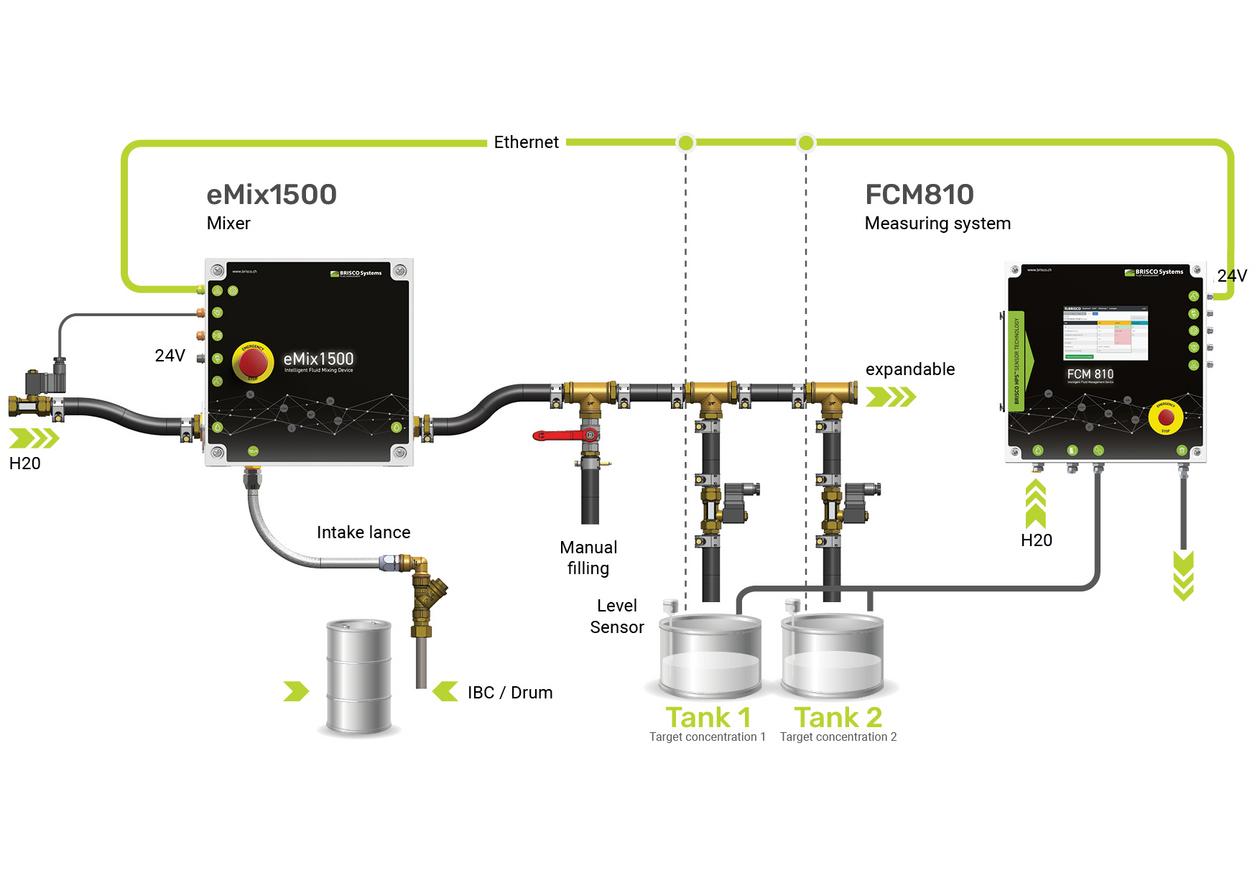

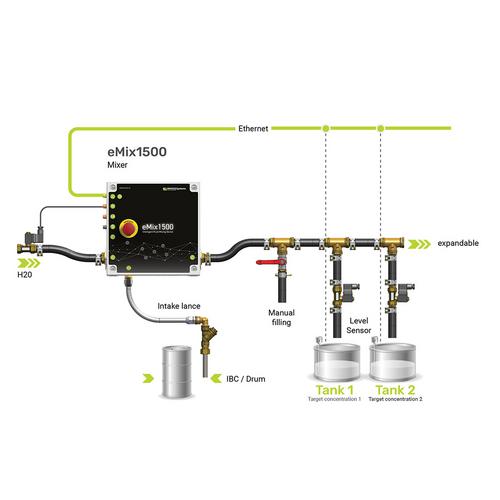

eMix1500 System

Keeps a constant concentration level

Automatic control of filling level

Individual control of up to 100 tanks

Latest mixing technology for the high-quality emulsions

Controls temperature to avoid KSS temperature shocks

Increases efficiency and productivity

The system automatically regulates the filling levels and independently calculates the concentrations of the emulsion to be tracked.

The FCM810 measures and monitors the cooling lubricant of the individual tanks fully automatically

Fluctuations in concentration and fill level are reduced to a minimum

Manual work steps can be automated

Automatic real-time measurement of pH value, concentration, conductivity and temperature

In combination with the eMix1500 fully automatic concentration control

The system automatically measures, monitors and doses the coolant in the individual tanks and automatically regulates the fill levels and concentrations.

Fluctuations in concentration and level are reduced to a minimum

Automation of manual work steps

Automatic real-time measurement of pH value, concentration, conductivity and temperature

Fully automatic concentration control in combination with the eMix1500

Manual sources of error are eliminated

Increased efficiency and productivity